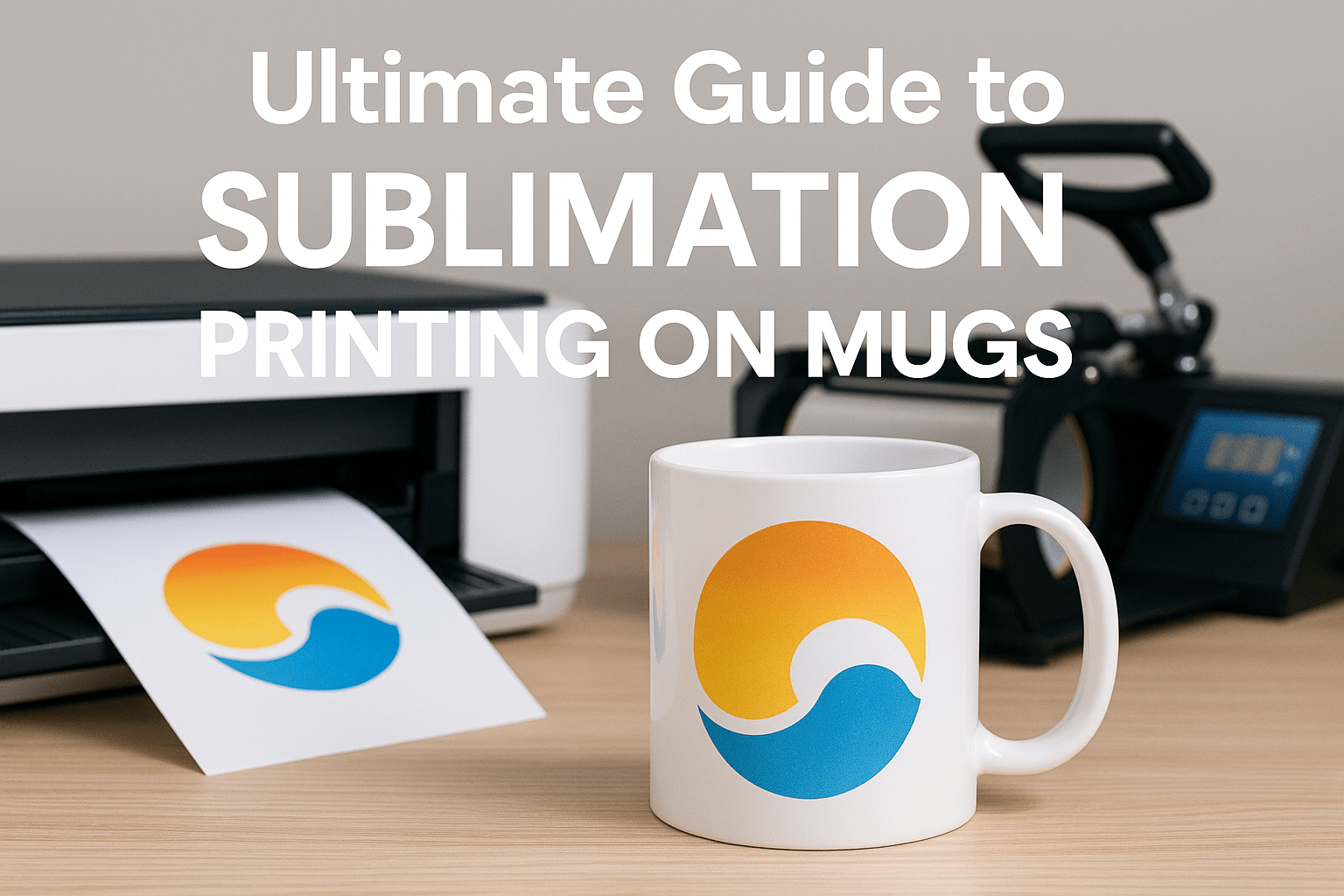

A Complete & Ultimate Guide to Sublimation Printing for Beginners, Hobbyists & Small Businesses

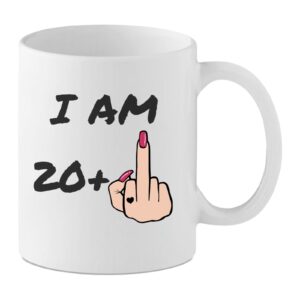

Sublimation printing on mugs has grown into one of the most profitable and accessible customisation methods for small craft businesses, print studios, and personalised-gift creators. Its strength lies in vibrant, permanent prints that won’t peel, crack, or fade — even after hundreds of washes.

This cornerstone guide walks you through every stage of the sublimation mug-printing process, including equipment requirements, artwork preparation, print settings, pressing techniques, troubleshooting, and optimisation tips for professional-quality results.

⭐ What Is Sublimation Printing?

Sublimation printing is a method where specially formulated sublimation inks transform from solid → gas → solid without becoming a liquid. When heated inside a mug press, the ink infuses directly into the polymer coating of a sublimation-ready mug.

Why Sublimation Works So Well on Mugs

- Produces permanent, dishwasher-safe designs

- Allows photo-quality prints

- Enables full-wrap graphics around the mug

- No texture — the print becomes part of the surface

- Fast and scalable for business use

🧰 Equipment You Need for Mug Sublimation

1. Sublimation Printer

Common beginner-friendly options include:

- Epson EcoTank models converted for sublimation

- Sawgrass SG500/1000 (purpose-built)

2. Sublimation Ink

Only sublimation ink will sublimate; regular ink will not transfer.

3. Sublimation Paper

High-quality paper prevents bleeding and gives sharper results.

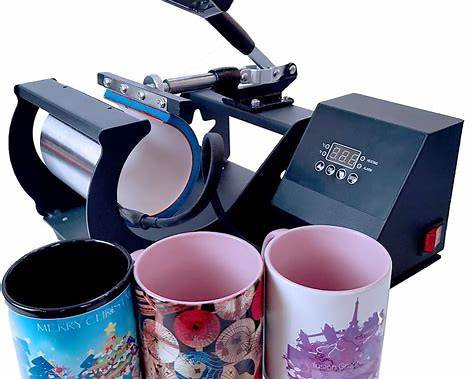

4. Heat Press for Mugs

Two main types:

- Clamp-style mug press (common for most makers)

- Convection oven designed for sublimation

5. Heat-resistant Tape / Adhesives

Prevents design shifting during pressing.

6. Sublimation-Coated Blank Mugs

Mugs must have a polymer coating; standard ceramic mugs do not work.

Optional Tools

- Heat gloves

- Teflon sheets

- Mug wrap bands (for oven method)

- Heat-resistant pads

🎨 Preparing Artwork for Sublimation Mugs

1. Choose the Right Colour Profile

Use RGB (preferably sRGB) — sublimation inks are optimised for it.

2. Set the Canvas Size

Standard sublimation mug wrap template for 11oz mug:

- Width: 20–21 cm (8–8.25 inches)

- Height: 9–10 cm (3.5–4 inches)

OR follow your mug press manufacturer’s template.

3. High-Resolution Images

Aim for 300 DPI to maintain sharpness.

4. Soft-Proofing

Most sublimation printers push colours more vibrant than screens show; soft-proof or run test prints before launch.

🔧 Step-by-Step Guide: How to Sublimate a Mug

STEP 1 — Print the Design

- Mirror your artwork

- Select High Quality or Photo print mode

- Use appropriate sublimation paper setting

- Allow the print to fully dry before handling

Top tip:

Let prints dry at least 10 minutes to avoid smudging.

STEP 2 — Prepare the Mug

- Clean the mug with alcohol or lint-free cloth

- Avoid fingerprints — oils cause uneven transfer

- Ensure mug is completely dry

STEP 3 — Position and Tape the Design

- Wrap the printed design tightly around the mug

- Tape from the edges inward to remove air bubbles

- Ensure no gaps between paper and mug

Top tip:

Use heat-resistant tape sparingly — too much can cause pressure issues.

STEP 4 — Set Up the Mug Press

Most mug presses use settings in this range:

| Mug Size | Temp | Time | Pressure |

|---|---|---|---|

| 11 oz | 180–200°C (356–392°F) | 160–210 sec | Medium–Firm |

| 15 oz | 180–200°C | 180–240 sec | Medium–Firm |

Always check your machine’s manual — settings vary.

STEP 5 — Press the Mug

- Insert mug into preheated press

- Lock it into place

- Allow the timer to run fully

- Carefully remove using heat gloves

STEP 6 — Remove Transfer Paper

- Peel paper away while still hot (unless using adhesive sheets requiring cold peel)

- Place mug on heat-resistant pad

- Let cool naturally

- Admire your permanent, vibrant print!

💡 Pro Tips for Professional Sublimation Results

- 🔸 1. Pressure Matters – Insufficient pressure leads to faded areas; too much causes ghosting.

- 🔸 2. Test Your Heat Press Regularly – Hot spots can ruin the edges of transfers.

- 🔸 3. Avoid Moisture – Humidity affects sublimation ink and paper. Store both in a sealed environment.

- 🔸 4. Use Bleed Areas – Extend backgrounds beyond trim lines to avoid white gaps.

- 🔸 5. Wrap Mugs Consistently – If scaling production, use jigs/templates for exact placement.

- 🔸 6. Remove Moisture from Mugs Before Pressing – A quick pre-press for 5–10 seconds can help eliminate moisture.

🧪 Common Problems & How to Fix Them

❌ Faded Prints

Causes:

- Low temperature

- Short press time

- Wrong paper side printed

- Moisture in mug/paper

Fix:

Increase time/heat slightly; pre-press mug; check printer settings.

❌ Blurry or Washed-Out Images

Causes:

- Design not fully dry

- Excessive pressure

- Low-resolution artwork

Fix:

Allow full drying; adjust press pressure; re-export artwork at 300 dpi.

❌ Ghosting / Shadowing

Causes:

- Paper shifted during pressing

- Too much or too little tape

- Mug not held firmly

Fix:

Tape securely, ensure consistent pressure, wrap paper tightly.

❌ Uneven Colour (Hot Spotting)

Causes:

- Uneven heat distribution

- Mug not centred in press

Fix:

Rotate mug halfway through pressing (for some presses) or adjust heater pad.

📦 Scaling Up: Sublimation Mug Business Tips

- 1. Batch Print & Press – Group similar colours/designs to minimise adjustments.

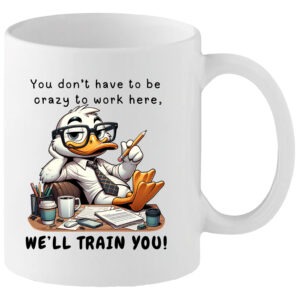

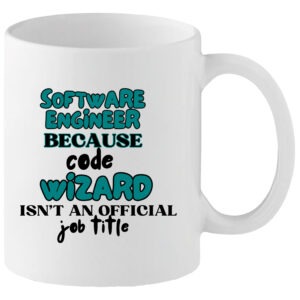

- 2. Offer Customisation Options – Names, photos, occasions = higher margins.

- 3. Create Mockups – Use digital mockups for online listings, reducing sample waste.

- 4. Maintain a Clean Workflow – Dust, oils, and fibres can create print defects.

- 5. Track Your Best-Selling Designs – Optimise production around proven styles.

🧾 Sublimation Printing FAQs

Can I use any ceramic mug for sublimation?

No. The mug must be polymer-coated for sublimation inks to bond.

Are sublimated mugs dishwasher safe?

Yes — they’re highly durable and resistant to fading.

Do I need a special printer for sublimation?

Yes. You must use a sublimation-capable printer with sublimation ink.

Is sublimation better than vinyl for mugs?

For durability, colour vibrancy, and longevity — yes.

🎉 Final Thoughts

Sublimation printing on mugs is one of the most reliable and accessible ways to create customised products with a professional finish. Whether you’re printing for your own craft shop, starting a personalised-gift business, or scaling up production, mastering the process is the key to consistent, vibrant, long-lasting results.